Malachite green can be synthetically produced through controlled chemical reactions using aromatic aldehydes and dimethylaniline; consistent results require precise temperatures between 60-80°C and acidic catalysts. If you remember one thing: the vibrant color emerges only after oxidation transforms the intermediate compounds - attempting shortcuts or household substitutions will yield unpredictable results.

Picture walking into a dyeing workshop where artisans debate malachite green. Some insist it's extracted from natural stones, others believe it’s as simple as mixing food coloring. "The color shifts under vinegar," one claims, while an online tutorial promises instant results with kitchen ingredients. Confusion often stems from its mineral-inspired name, over-simplified DIY guides, and the dramatic visual transformation during synthesis. This article clarifies eight key aspects using verifiable chemical principles explained through simple scenarios.

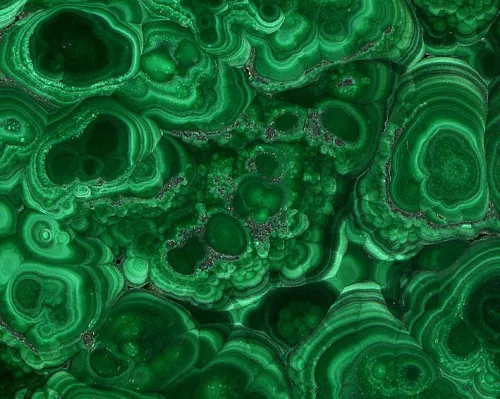

Imagine your friend excitedly shows you "malachite powder" bought online, convinced it’s pulverized mineral. Many assume the dye comes directly from malachite stones because of its name and similar hue. This misconception spreads through mineralogy blogs and marketing language that romanticizes "earth pigments."

In reality, malachite green is man-made through chemical reactions. The molecular structure consists of a central carbon atom bonded to three aromatic rings and an iminium group, forming a triphenylmethane backbone. Commercial production typically achieves 85-99% purity through controlled crystallization without natural minerals involved.

When you encounter malachite green products, ask: Does the label specify "synthetic dye"? Check if the manufacturer shares technical documentation rather than vague "mineral-inspired" marketing. Genuine producers will transparently disclose synthetic origins and chemical composition.

Picture this: An online tutorial claims mixing turmeric and baking soda creates "organic malachite." Such DIY attempts overlook that even high-quality materials require precise aromatic aldehydes and dimethylaniline. The myth thrives because basic chemistry kits often exclude specialized precursors.

The clearer way to see it is: Production requires condensation reactions at elevated temperatures forming the basic structure, followed by oxidation steps transforming the leuco base into the colored cationic form. Under acidic conditions with catalysts like hydrochloric acid, electrophilic substitution occurs enabling the final optical properties.

Before attempting any recipe, verify two things: 1) Does it list aromatic aldehydes as primary reactants? 2) Does it specify oxidation reagents? These technical details are your litmus test for reliable formulas.

A craft influencer demonstrates dye-making using mason jars with caption: "Equipment optional!" Many believe household containers suffice since the process seems visually straightforward. This assumption persists because hobbyist videos often downplay material requirements.

Technically speaking, synthesis requires corrosion-resistant vessels and temperature controls to manage the acidic environment. Standard batch scales from 200g to 5kg need reaction tools that withstand hydrochloric acid vapor during the 60-80°C range. Environmental controls prevent hazardous exposure that mason jars cannot contain.

If you encounter small-batch recipes, assess equipment lists: Look for glass-lined containers or borosilicate reactors noted alongside PPE mentions. Missing corrosion warnings indicates incomplete guidance. Responsible methods prioritize ventilation systems over "easy setup" claims.

Visualize your chemistry teacher demonstrating malachite synthesis: Clear liquids combine but remain colorless until heating triggers magical greening. Newcomers often misinterpret this transformation as mere pigment mixing because early stages show no visual cues about the final color.

Reality unfolds in three phases: Condensation first forms a leuco base at around 65°C, creating invisible intermediates. Oxidation then triggers the electron reorganization that yields the final coloration. Crystal formation completes this process during cooling phases where metallic-green needles become visible in the mixture.

When observing synthesis, pay attention to: 1) Temperature milestones over visual changes 2) Timing when oxidizing agents are introduced. Consistent results depend less on "perfect green immediately" and more on methodical thermal controls.

Imagine purchasing two identical malachite solutions that stain shirts differently. The frustration arises because we expect "green" to behave uniformly, while pH environments can alter photochemical behaviors unseen by naked eye.

The compound exhibits pH-responsive behavior. Though typically absorbing light strongest at 620nm wavelengths, acidic environments may shift it towards blue-green or yellow spectrums. Its fine crystalline structure tends to form metallic-looking flakes but long-term light exposure can cause photodecomposition that reduces intensity unexpectedly.

For consistent results: Check solution pH before application. Water solubility allows concentrations up to 10% weight but test swatches under intended lighting conditions first. Store samples away from UV sources even during short-term projects.

A textile artist opens last year's malachite stock to find faded solutions. "But I kept it sealed!" The surprise comes from underestimating how heat, light, and solvent choices conspire against stability.

The dye displays moderate thermal stability below 100°C but photodecomposition accelerates dramatically under UV exposure—whether from windows or photo-documentation lamps. Similarly, solubility patterns affect storage: While water maintains uniform solutions, transfers to non-polar solvents tend to compromise integrity.

For storage: 1) Always note batch dates and storage temperature 2) Use amber glass 3) Reject organic solvents unless explicitly formulated for them. Test small samples monthly by comparing against initial swatch cards rather than trusting "sealed" promises.

Picture a ceramic studio confidently using malachite solution for all glazes. While water solubility enables diverse applications, assumptions about universal suitability overlook context-sensitive variables like heat thresholds.

Because color intensity remains consistent across batches under equivalent conditions, large-scale textile processors rely on consistent dye formulation. Performance limits emerge above 100°C, where thermal decomposition begins. Non-polar systems pose challenges since solubility dramatically decreases in oil-based solvents.

Before application: First determine whether temperature exposure may exceed safety thresholds. When exploring new mediums (fabrics vs ceramics vs paints), create test panels documenting both color adherence and stability under intended conditions.

A workshop attendee mixes the "identical formula" but gets different yields—unaware that cooling rate variations impact crystallization efficiency. Scaling complications often surprise beginners who assume linear ingredient multiplication guarantees identical results.

Batch yields between 200g and 5kg react differently to cooling parameters, affecting crystal size distribution. Final composition may include trace benzaldehyde derivatives depending on precursor purity. Maintaining safe working conditions requires vapor containment systems scaled proportionally to batch size.

When adjusting scales: Document cooling phase durations alongside ingredient ratios. Compare new batch crystal patterns against prior successful samples. Monitor environmental controls more rigorously as batch size increases.

Recalling our dye workshop visitor: Next time they encounter vibrant greens, they'll notice how manufacturers articulate origins (natural mineral vs. synthetic), check whether equipment specs match chemical reactivity, and question unexpected color shifts by requesting pH documentation. Focus on understanding precursor chemical reactions rather than chasing instant results.

Q: Will substituting benzaldehyde with other aldehydes create different colors?

A: Core structure modification may yield different color outcomes but "malachite green" specifically requires benzaldehyde derivatives. Alternative aldehydes typically produce other triphenylmethane dyes with distinct optical properties.

Q: Can I remelt crystallized product to improve consistency?

A: Repeated heating can promote decomposition as thermal stability thresholds may be exceeded. Recrystallization using appropriate solvents tends to deliver better consistency without compromising molecular integrity.

Q: Why does my solution sometimes form blue surface films?

A: Oxygen exposure before full conversion might create oxidation byproducts. Strict reaction atmosphere controls help prevent premature surface reactions during synthesis.